In modern smart factories,

How can abstract data become intuitive and tangible?

How can hidden risks and hazards be warned in advance?

How can passive management shift to proactive control?

The answer lies within

— Luculent Smart Digital Twin Platform

With it,

The factory is endowed with "intelligent life,"

Equipment can "speak,"

And decision-making can "think autonomously"!

Digital Assets "Come Alive"

Seamless Production Coordination

Through this platform, every piece of equipment in the factory has its exclusive "digital twin," paired with a unique KKS code "ID." From design drawings and installation to commissioning, operation, and daily maintenance, full lifecycle data can be seamlessly integrated into the "digital asset library" with one click via AI models.

The transition from construction to production is smooth and steady, achieving a deep leap from "project delivery" to "capability handover," ensuring digital capabilities truly serve the enterprise.

Safety Protection "Made Visible"

Risks and Hazards "Avoided Early"

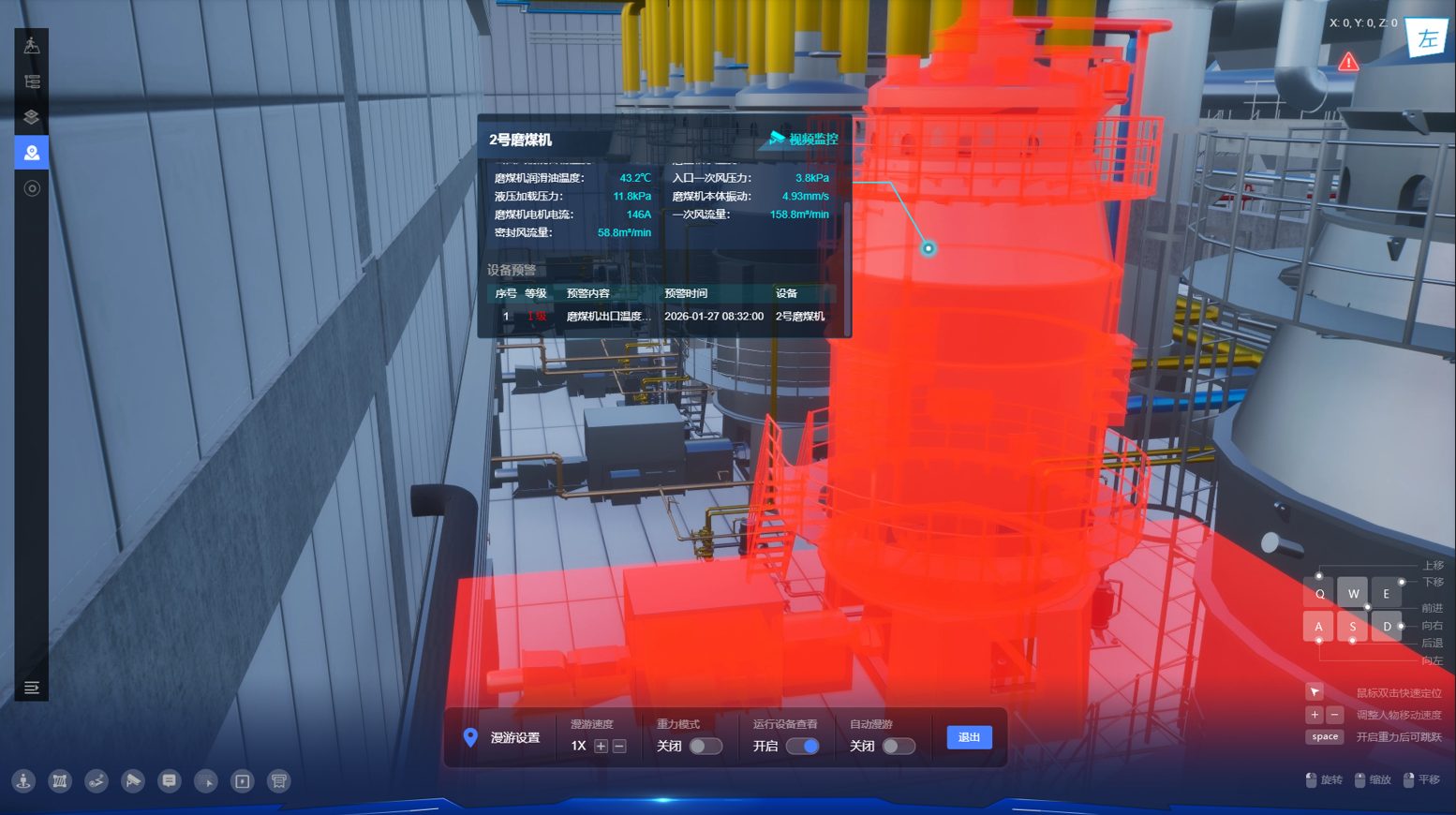

On the production floor, 3D positioning technology acts like an "intelligent tracker," locking onto the location and movement paths of every worker in real time, with dynamic trajectories clearly traceable. Critical areas are equipped with electronic fences—once someone crosses the boundary, the system immediately alerts and links to surveillance video, providing dual safeguards to curb compliance risks at the source.

For safety risk prevention and control, the platform uses a four-color map for hierarchical labeling and dynamic updates, making risk points intuitive and clear, and ensuring precise implementation of control measures without oversight.

Notably, the platform comes with an AI "keen eye" that automatically identifies issues such as non-standard personnel operations, abnormal equipment performance, and environmental safety hazards. It accurately marks problem locations on the 3D model and issues warnings, eliminating the need for manual inspections and providing 360° comprehensive protection for production safety.

Smart Operations "Boost Efficiency"

Management Coordination "More Effortless"

Entering the digital twin platform is like opening a "god's perspective": immerse yourself in a virtual tour of the factory, where the operational status of every piece of equipment and real-time production process data are all displayed on a "single screen." The visualization here goes beyond "seeing" to achieving the deeper value of "controllable, optimizable, and manageable."

AI models act as "divine calculators," predicting equipment failures in advance, optimizing production rhythms, efficiently allocating resources, and providing the best decision-making solutions, making operations management more forward-looking and scientific. Empowered by the platform, warning accuracy exceeds 95%, and equipment lifespan is extended by 3–5 years.

Paired with robotic automated inspections, inspection routes and detection data are synchronized in real time and fully traceable, eliminating the need for manual labor while avoiding inspection oversights. This "digital-intelligent" combination drives a comprehensive upgrade of traditional production management, boosting production efficiency exponentially.

Virtual Maintenance "Trains Real Skills"

Maintenance Operations "More Efficient"

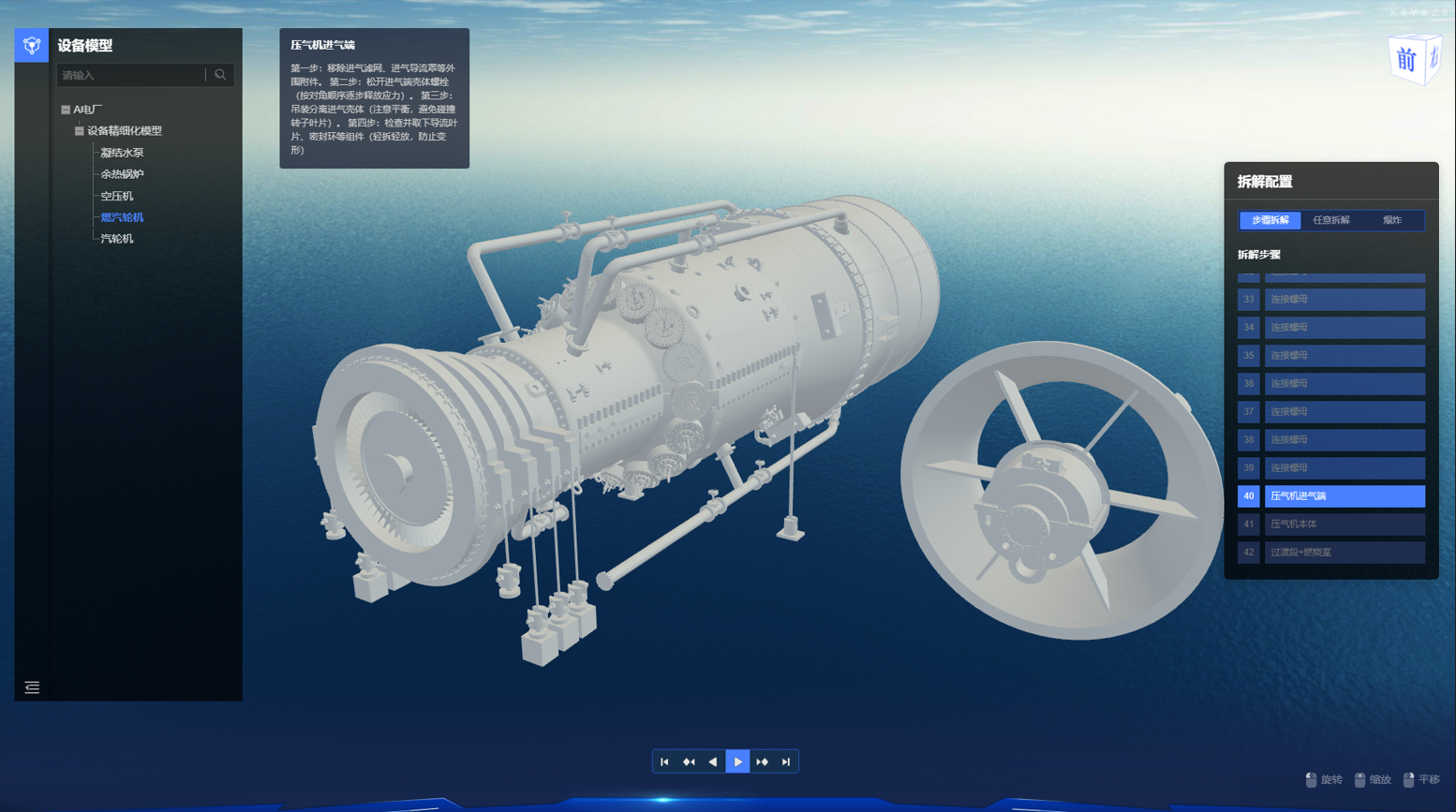

Complex internal equipment structures? The 3D model "penetrates" to reveal the essence, clearly presenting the construction of each component and their interrelationships—like working with a "transparent blueprint."

The platform can also simulate the entire process of equipment disassembly. Maintenance personnel can engage in "immersive hands-on practice" by following standardized steps, with precise control over each operation’s specifications and precautions, completely breaking away from reliance on "old experience." This not only significantly reduces the risk of operational errors but also markedly improves maintenance efficiency, ushering equipment maintenance into a new era of "visualization and refinement."

Making Decisions More Intuitive,

Making Coordination More Efficient,

Making Intelligence Accessible at Your Fingertips,

Luculent Digital Twin Platform,

Creating a New Paradigm for Smart Factories with AI!