Western International Holdings Limited (referred to as "Western Holdings") is a conglomerate affiliated with China Western Cement Limited (stock code 2233.HK), a Hong Kong-listed company. It operates as an integrated enterprise, encompassing cement production and sales, corporate management, and industrial investment. The company closely follows the development of China's "Belt and Road" initiative and seizes the opportunity to expand cement production capacity in overseas markets, particularly in emerging markets in West Africa, Central and Southern Africa, and East Africa. Currently, it has invested in constructing a new 5000t/d dry-process cement clinker production line in Mozambique and has completed a 140t/d One Furnace Two Lines flat pull method glass production line in the Republic of Congo.

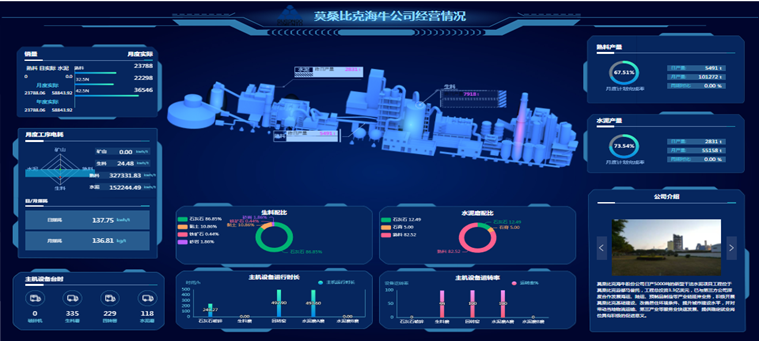

Luculent has developed an integrated intelligent control information system for Western Holdings, which proposes new ideas and objectives based on an understanding of the company's existing application systems. The aim is to deepen the integration of management ideologies and create a production control platform with Western Holdings' management characteristics. This platform will serve as the foundation for gradually advancing the construction of intelligent factories within the company.

The Western Holdings integrated intelligent control information system integrates data from various dimensions such as process data, quality control data, intelligent instruments, equipment maintenance information, energy centers, inventory information, inbound and outbound logistics, personnel information, and team information. It builds smart factories, establishes a group-wide big data center, and covers projects including Ethiopian group and subsidiary cement plants.

Key features of the Western Holdings control platform:

Group application: A two-tier (group, cement plant) application model centrally deployed by the group.

Group application: A two-tier (group, cement plant) application model centrally deployed by the group.

International version: Language options include Chinese, English, French, and Portuguese.

International version: Language options include Chinese, English, French, and Portuguese.

Cross-national usage: Projects are distributed across multiple African countries, including Ethiopia and Mozambique.

Cross-national usage: Projects are distributed across multiple African countries, including Ethiopia and Mozambique.

High degree of productization: Productization rate >= 90%, with less than 10% of personalized form applications.

High degree of productization: Productization rate >= 90%, with less than 10% of personalized form applications.

Strong adaptability: Different factory modeling, data collection, process construction, indicator system establishment, and multi-dimensional display can be achieved through system configuration. Implementation cycles are short, and results are quickly obtained.

Strong adaptability: Different factory modeling, data collection, process construction, indicator system establishment, and multi-dimensional display can be achieved through system configuration. Implementation cycles are short, and results are quickly obtained.